Our HK exhibition echnological Evolution of High Power IGBT Cooling Plate

publisherGavin Zhang

time2016/10/20

- The development history of the High Power IGBT Cooling Plate is a history of continuous innovation in pursuit of high - efficiency heat dissipation.

Early cooling plate technologies were relatively simple, mainly adopting air - cooling or single - liquid - cooling methods, with limited heat dissipation efficiency and difficulty in meeting the growing high - power demands. With the continuous progress of materials science and manufacturing processes, new materials and innovative design concepts have been widely applied in the research and development of cooling plates.

For example, in terms of materials, high - performance composite materials such as aluminum silicon carbide (AlSiC) have gradually emerged. AlSiC has high thermal conductivity and good thermal expansion matching characteristics with semiconductor chips, which can effectively improve heat dissipation performance and prevent device damage caused by thermal stress. Its low density and high specific stiffness make it perform outstandingly in application scenarios with strict requirements for weight and seismic performance, such as the aerospace and rail transportation industries.

In terms of manufacturing processes, the application of advanced technologies such as friction stir welding and vacuum brazing has made the internal flow channel design of the cooling plate more refined, and the flow of the coolant more uniform, thus greatly improving the heat dissipation efficiency. In addition, the development of micro - channel cooling technology, by constructing a micro - flow channel structure inside the cooling plate, increases the contact area between the coolant and the heating device, further enhancing the heat dissipation effect.

II. Key Role in Industry Applications

A. Electric Vehicle Field

In the power system of electric vehicles, the High Power IGBT module is responsible for controlling the drive and energy conversion of the motor. A large amount of heat generated during its operation needs to be dissipated in a timely manner. A high - performance IGBT cooling plate can ensure that the IGBT module remains within an appropriate operating temperature range under various working conditions, thereby improving the efficiency and reliability of the motor and extending the service life of the battery. For example, some leading electric vehicle manufacturers have adopted customized liquid - cooled IGBT cooling plates. By optimizing the flow path of the coolant and the heat dissipation structure, the junction temperature of the IGBT module has been effectively reduced, improving the overall vehicle performance and driving range.

B. Industrial Automation Field

Core components such as frequency converters and servo drives in industrial automation equipment widely use High Power IGBT. Stable heat dissipation is crucial for ensuring the high - precision operation and long - term stable operation of these devices. The application of IGBT cooling plates can effectively reduce the failure rate of equipment, improve production efficiency, and reduce maintenance costs. In industries with extremely high requirements for production continuity, such as steel and chemical industries, a reliable heat dissipation solution is even more indispensable.

C. Smart Grid Field

In the power transmission and transformation links of the smart grid, High Power IGBT is used in key technologies such as high - voltage direct - current transmission (HVDC) and flexible alternating - current transmission systems (FACTS). The IGBT cooling plate needs to ensure stable heat dissipation performance in a harsh working environment of high voltage and large current. Advanced cooling technologies can not only improve the power transmission efficiency of the grid, reduce power consumption, but also enhance the stability and reliability of the grid, ensuring the safe supply of electricity.

III. Market Prospect and Competitive Landscape

With the continuous growth of demand for High Power IGBT in various industries, the IGBT cooling plate market is showing a booming development trend. According to market research institutions, in the next few years, the global IGBT cooling plate market size will continue to expand, and the annual growth rate is expected to remain at a relatively high level.

In terms of the competitive landscape, a number of competitive enterprises have emerged in the market. Some traditional heat dissipation solution providers, relying on their rich experience and technical accumulation, have occupied a certain share in the market. At the same time, some emerging technology enterprises have risen rapidly through continuous technological innovation and product optimization, becoming strong competitors in the market. These enterprises are constantly making efforts in product research and development, manufacturing, and customer service, committed to providing customers with more efficient and reliable High Power IGBT Cooling Plate solutions.

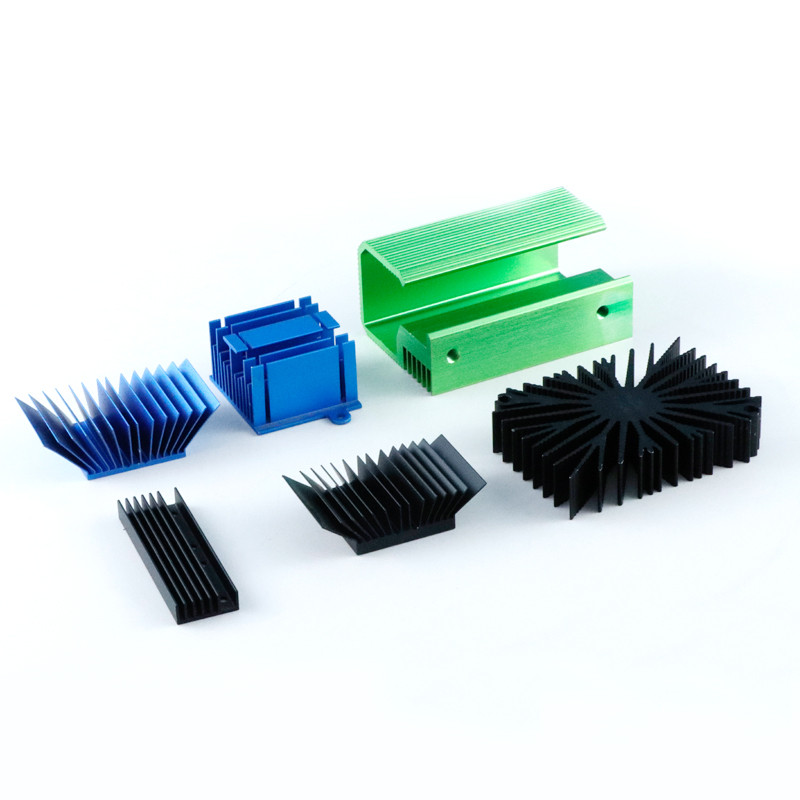

Over 13 years in OEM manufacturing experience in the field of heat sink industry.

Contains:Aluminum extrusion heatsink,Cold forging heatsink,hot pipe and Fan.

Dongguan Ruiquan Hardware Electronics Co., Ltd.

Add: Xinzeng Industrial Zone, Wang Zhongming Road, Shipai Town, Dongguan City,Guangdong province, P.R.C.

Tel: +86-769-38800708,ext.828 Fax: +86-769-38800709

Mobile: +86-13609699895 Skype: heatsink61

QQ:2733632794 trademanager:cn1000769666

E-mail:rq4..........com

Tel: +86-769-38800708,ext.828 Fax: +86-769-38800709

Mobile: +86-13609699895 Skype: heatsink61

QQ:2733632794 trademanager:cn1000769666

E-mail:rq4..........com